LUMiReader® X-Ray Product information

LUMiReader® X-Ray - illuminating even the most concentrated emulsions & suspensions

| In-situ analysis of transparent as well as opaque dispersions | High resolution of phase separation of multicomponent systems |

| No dilution of emulsions or suspensions | Detect concentration gradients within phases and sediment |

| Signal does not depend on particle shape | Determine mean and space resolved packing sediment densities |

| See/understand complex dispersion behaviour | Use any continuous phase of dispersing agent |

The LUMiReader X-Ray is the first dispersion analyser designed for one purpose only: to study dispersability, stability, separation, and consolidation phenomena for completely transparent to completely opaque emulsions, suspension, sludges, slurries, foams and powders in real-time. For the first time ever, illuminate your sample instantaneously from top to bottom. Solve your most challenging dispersion problems with complete insight. Go places light cannot.

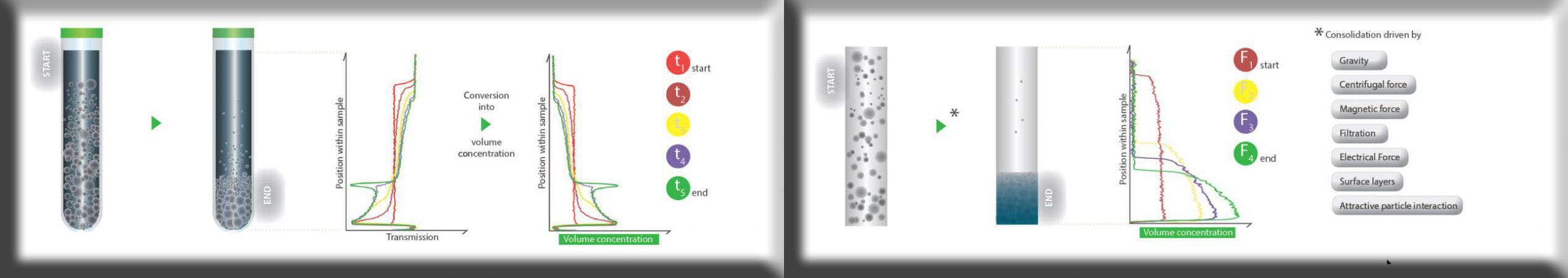

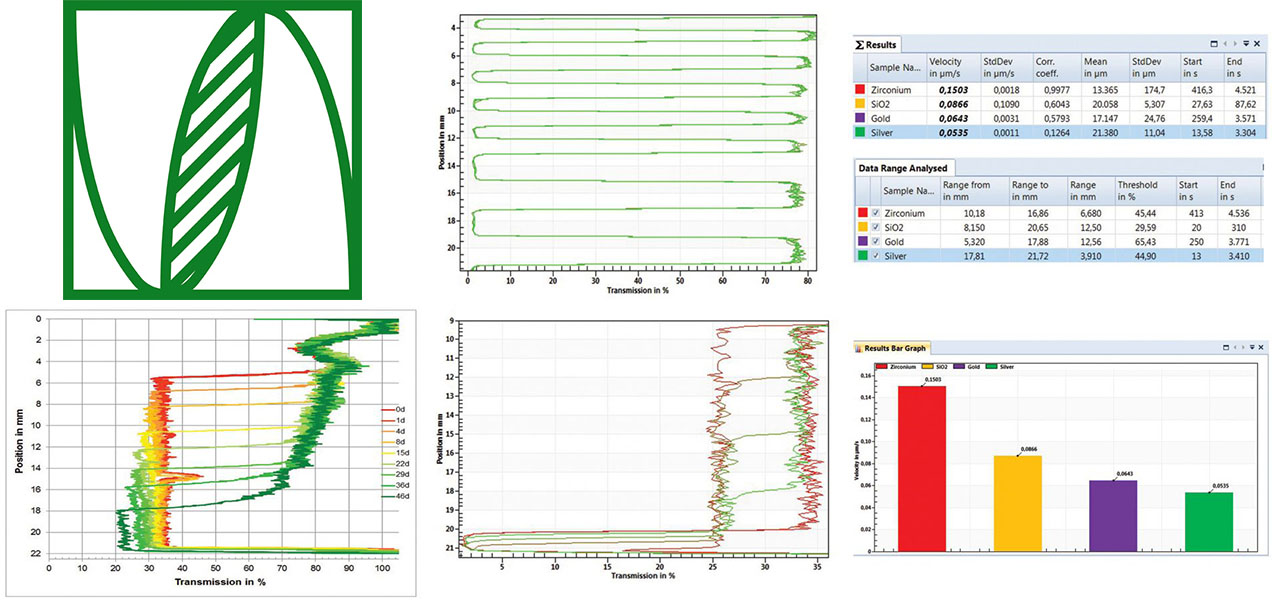

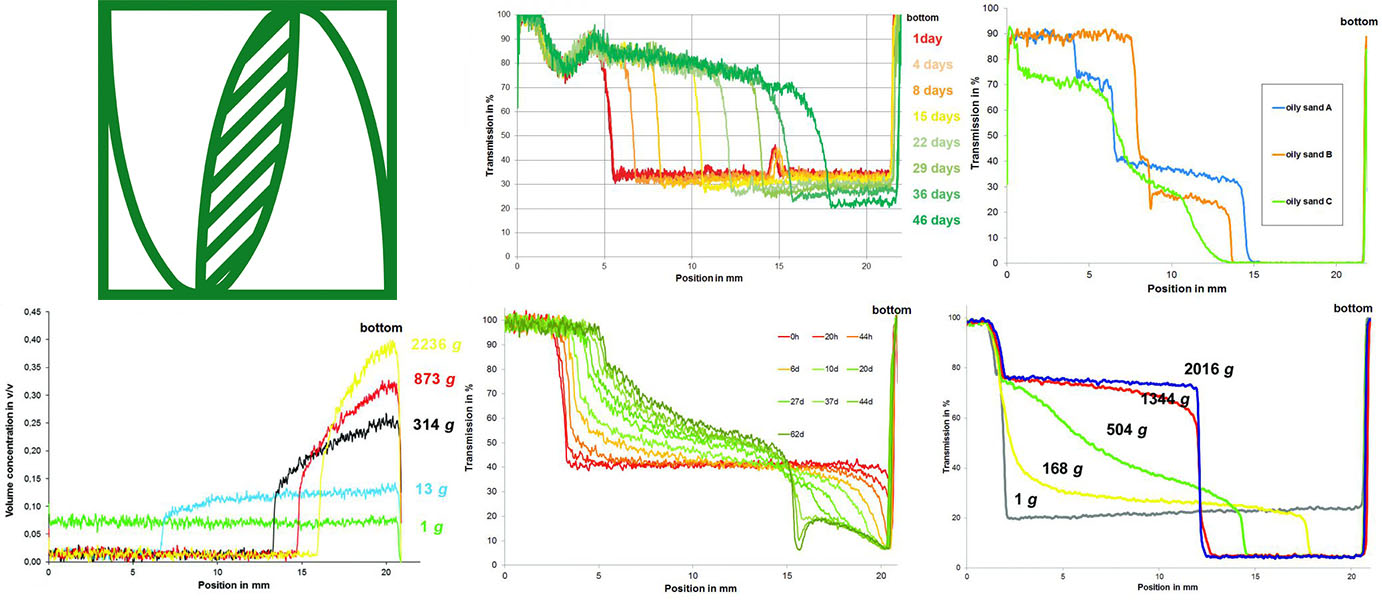

Our patented solution combines X-ray vision with the proven STEP-Technology, permitting highest spatial resolution, short sampling intervals and powerful detection technique. The LUMiReader X-Ray employs monoenergetic and parallel X-rays with the help of a special crystal. More than 1,600 detectors record the transmitted beam, giving an unprecedented resolution over the entire sample cell of 20 mm height. Kinetics of instantaneous recorded transmission profiles across your whole sample are converted into stability and separation rates. Particle concentration, sediment packing density and X-ray attenuation can also be calculated based on the extinction profiles.

The obtained Space- and Time-resolved Extinction Profiles allow you to measure and understand particle stability, phase separation, and sediment consolidation in systems that where up to now, unknown frontiers of science and technology. You now can optimize your formulation, measure its stability, and perform accurate shelf life tests, regardless of the shape or concentration of your dispersed particles and droplets. In-situ, real-time, non-invasive and non-destructive.

Typical applications are ceramics, cosmetics, pharmaceutics, paint & pigments, construction materials and fillers, as well as mining and petrol industry dealing with complex emulsions, slurries and sludges.

No more dilutions, no more guess work, no more unexpected surprises. Analyse and understand your sample as is, no matter how opaque or concentrated your formulation is.

For all those instances where you need to understand transparent or opaque dispersions, foams, emulsions, or clear microemulsions where dilution is impossible or has unknown side-effects and consequences there is a solution now, and you are looking right at it.

There are many claims out there about the ability to analyze concentrated systems. When pressed however, it turns out that what is concentrated to one person is dilute to another. With that in mind, and wanting to avoid any confusion, all we can state unequivocally is that the LUMiReader X-Ray was designed with one goal in mind: to allow you to analyze and understand concentrated and totally opaque emulsions and suspensions.

How concentrated? As high as you want to go. As opaque as you want it to be. Top to bottom, instantaneously. Yes. Really. No other technology can do this. It is not even close.

The LUMiReader X-Ray is simple to operate. It comes certified, factory pre-calibrated and is ready-to-go.

LUMiReader® X-Ray Technology

![]() STEP-Technology® – Allowing you to look at the whole sample.

STEP-Technology® – Allowing you to look at the whole sample.

At the heart of the LUMiReader X-Ray® lies the cutting-edge STEP-Technology (Space- and Time-resolved Extinction Profiles). This process gives you flexibility, unprecedented insight, and understanding about your emulsion– and suspension– based product.

By illuminating your dispersion across its entirety, and by having many thousand detectors measure the x-ray source extinction profile instantaneously, we can detect even the smallest sample components and changes. Transmission is then converted into extinction and particle concentration may be calculated.

The obtained Space- and Time-resolved Extinction Profiles allow you to measure and understand particle stability, phase separation, and sediment consolidation in systems that where up to now, unknown frontiers of science and technology.

STEP-Technology® gives you power, freedom, and flexibility. You can choose to analyse a single point in your sample, multiple points, or across the whole sample.

You can analyse particles in their dispersed phase, as they are settling and creaming, and during the consolidation phase at real-world concentrations. For all those instances where you need to understand dry powder mixtures, opaque dispersions, foams, emulsions, or clear microemulsions where dilution is impossible or has unknown side-effects and consequences there is a solution now, and you are looking right at it.

The choice is yours. Whether it is for research and development, quality control, or product optimization, the LUMiReader® X-Ray puts you light years ahead of your competition.

LUMiReader® X-Ray Software

SEPView® - Your window to dispersion analysis

SEPView® - Your window to dispersion analysis

| Windows 7 and 8 based | Analysis templates |

| Plug & play, pack & go | Zoom in and out of any area of interest |

| Individual user customization | Full SOP concept (Creation, capture, data analysis) |

| Comparison of old and new measurements | Comprehensive database security and full audit log |

| Complies with 21 CFR Part 11 | 18 different tools to understand (quantify) even the most complicated dispersion: - Time lapse measurement replay - Dispersion fingerprint - Clarification - Instability index - Phase separation - Sedimentation and creaming velocities - First derivative of integral transmission - Linear X-ray attenuation coefficient |

SEPView® is a comprehensive database driven software solution. Whether you want to perform particle size measurements, stability analysis, determine creaming or sedimentation rates, predict shelf-life, examine flocculation and sedimentation consolidation, determine the degree of magnetization of your dispersed particles, or accurately calculate the particle density: with the help of SEPView you can do all this and more.

SEPView controls the instrument and provides functions for data management, visualisation, analysis and result documentation.

All information (calibration data, programmed measurement methods, comments, transmission profiles, settings etc) is stored in one database, no file management required.

Fast access to validation and measurement results and sample information is guaranteed. Comparison of sample data from different measurements is easily achieved.

Different program components are provided for the qualitative and quantitative analysis of the samples, e.g.

- for the clarification

- the Integral Transmission

- for settling, creaming & consolidation

- the Front Tracking

- the PSA-Module for the calculation of the particle size distribution.

The included animation tool displays the recorded measurement data with programmable playback parameters for easy recognition & identification of complex separation phenomena. Standard database functions like import & export of measurements and results, filtration of database content by various criteria, user and database administration are supported by SEPView.

The program supports different languages and different systems of units. The modular and object oriented design of the software provides easy extension and customizing opportunities on customer's request, i.e. for special R&D or QC tasks. SEPView complies to CFR 21 Part 11 for special R&D or QC tasks.

LUMiReader® X-Ray Industrial Application

The modern measuring equipment made by LUM for comprehensive qualitative and quantitative characterization of dispersions is used in a large variety of different industrial and research facilities, dealing with innumerable materials.

To name few examples:

- Abrasives

- Batteries

- Carbon black

- Catalysts

- Coated particles

- Cosmetics

- Ceramics

- Construction materials

- Lubricants

- Magnetic particles

- Microemulsions

- Metals

- Mineral powders

- Nanosuspensions

- Oil sands

- Paints

- Pigments

- Rigid foams

- Silicone emulsions

- Solid electrolytes

LUMiReader® X-Ray Specification

| Measurement principle | Monochromatic X-ray attenuation |

| Phase separation | High concentrated dispersions (transparent or opaque) |

| In situ sediment analysis | Packing density and structure |

| Stability analysis | From seconds to days or weeks |

| Consolidation measurement | in combination with LUMiFuge, LUMiSizer |

| Conformity | ISO/TR 13097; CFR 21 Part 11 |

| Channels | Suspensions, Emulsions, Suspo-Emulsions, Sludges, Slurries, Foams & Powders |

| Samples | 1 sample |

| Volume | 0.3 ml to 1.6 ml |

| Concentration | Up to 100 Vol% |

| Particle | any shape, from nano to microscale, no density restriction |

| Source | Monoenergetic X-ray, 17.48 keV, max 20 W at 40k V, air and oil cooled |

| Monochromator | Graphite |

| Disturbance free | No moving parts |

| Dimensions (WxHxD), Weight | 47 x 24 x 44 cm, 25 kg |

| Power supply | 24 V, 220 W, Adapter (100 V to 240 V) included |

| Safety | Fully radiation protected system; Radiation < 1 µSv/h (BfS 03/13 V RöV) |

| Radiation control requirements | None. Instrument can be used anywhere |